Challenge

This Case Study is based on information provided by the AKT2I partners.

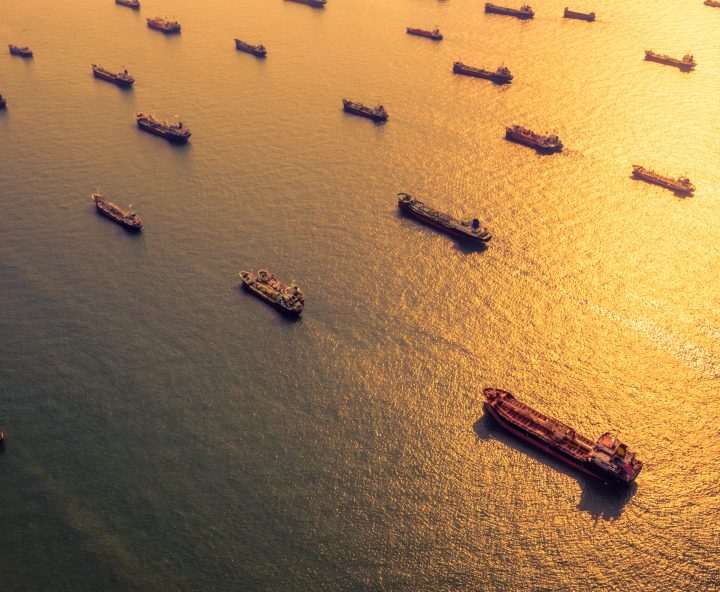

The global marine vessel market was valued at USD 165.12 billion in 2021, and it is expected to reach a value of USD 191.25 billion by 2028.* The growing size of the global maritime fleet calls for innovation in energy efficiency technologies, and that is exactly what Silverstream Technologies specialises in.

Named fourth fastest growing company in Europe by the Financial Times in its FT1000 report earlier this year, Silverstream Technologies is a world leader in maritime clean technology and has a patented air lubrication system (ALS), the Silverstream® System, which fundamentally changes the interaction between water and a vessel.

It is the resistance between the hull and the water which causes the biggest energy cost to a vessel’s operation; and the Silverstream® System decreases this friction, dramatically reducing fuel consumption and associated emissions, regardless of fuel type.

Silverstream Technologies entered in to an AKT2I partnership with Newcastle University whose unique large scale cavitation tunnel (a closed loop water flume) would enable the partners to develop new experimental capability to further exploit the potential of ALS. This AKT2I partnership was the first time that the two partners had worked together, bringing together a very well-matched fit of skills, knowledge, capabilities, facilities, experience, and ambition.

Outcome

Experimental testing is essential to fully exploit the potential of ALS but has only been possible in very large commercial testing facilities outside the UK that are not well suited to exploration of ‘what-ifs’.

Newcastle University has the capability to lead research in this field, building from strong foundations in experimental ship hydrodynamics and thanks to their cavitation tunnel, which holds huge potential for innovative ALS research.

Longer term the partnership could lead international research investigating the underlying science of ALS. In turn this could enable further technology development, expand industry adoption, and maintain Silverstream as market leaders.

Developing a test rig to innovate ALS

The project focused on the design, manufacture, and validation of a bespoke test rig to interface variants of Silverstream’s technology in Newcastle’s cavitation tunnel. The focus on the rig development also enabled the partners to effectively share knowledge on their respective capabilities and needs.

The design work showed that, prior to manufacture, the feasibility of air injection into the tunnel needed confirming, especially the challenge of air recirculation which could compromise test quality. The project responded by developing an innovative concept test using existing laboratory equipment.

The design optimisation and validation work produced final design drawings, a testing specification, an outline testing procedure flow chart and a list of ancillary equipment and instrumentation. Manufacture is now out to tender, anticipating fabrication in summer 2023 aligning with post-project collaboration activities.

Impact

The main achievement of the AKT2I project is a manufacture-ready design and specification for a bespoke test rig for Silverstream’s air lubrication system (ALS) technology interfaced to Newcastle’s cavitation tunnel.

The discoveries from the AKT2I project were driven by the rig design process and are significant for future collaboration between the partners.

The AKT2I positively demonstrated the overall viability of air lubrication experimentation in Newcastle’s cavitation tunnel. The project demonstrated further opportunities for broader research in ALS than originally anticipated, and it was successful in adapting the rig design to encompass this additionality.

The partners commit to completing the initial test rig validation post-project, with the intention to produce a journal paper documenting the academic findings and future potential of the experimental approach.

Further opportunities will be realised by future collaboration between the partners, and potentially several other third parties including Southampton University and Akzo Nobel. The partners believe these collaborations will grow Silverstream’s industry leadership, leading to substantially increased sales, and position Newcastle University as an international research leader in this area.

What they say

“The project confirmed the feasibility of the rig design for experimental works. Without the support the work would not have been completed in the UK nor operational until 2024. The support gained should allow for the facility to be operational within 2023, accelerating value delivery through Silverstream’s R&D portfolio.”

Further information

Without AK2I support, the partners confirmed that this innovation concept would not have progressed to the extent that it has.

If you’d like to find out more about this project, please contact Simon Benson: simon.benson@newcastle.ac.uk or David Connolly: david.connolly@silverstream-tech.com